milling machine parts and functions ppt

Column and Base Knee Saddle and Swivel Table Power Feed Mechanism Table Spindle Over Arm Overhanging Arm Arbor Support and Ram. An adjustable overhead arm containing one or more arbor supports projects forward from the top of the column.

Cnc Machining Vs Conventional Machining Emc Precision

Meaning of Milling Machine.

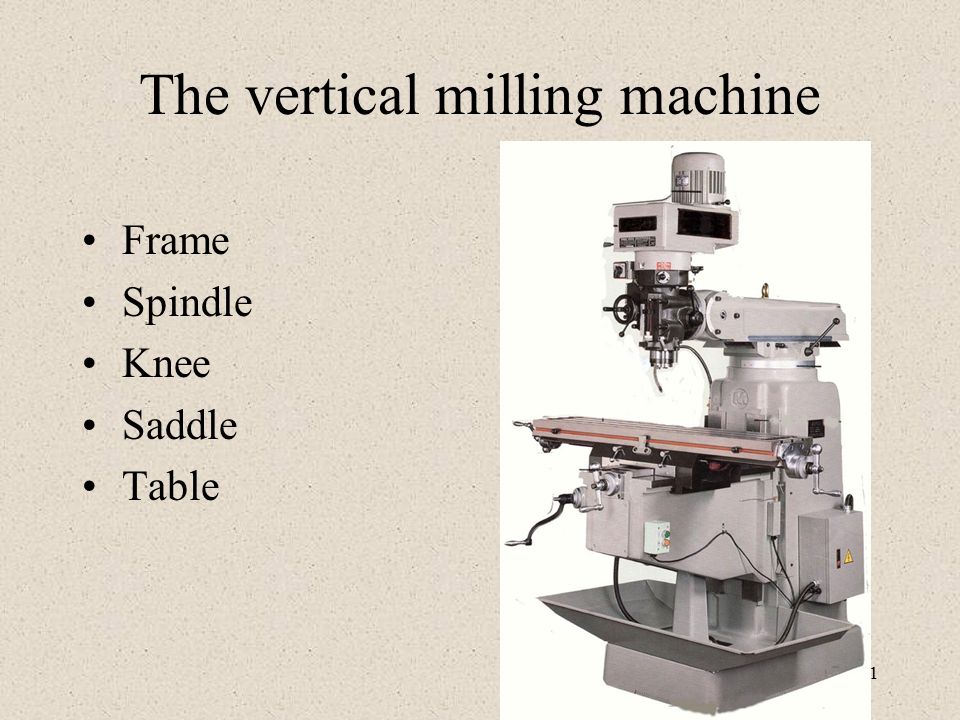

. The milling machine part can move transversely in and out on the column by a hand level. Milling Machines Session 13 Vertical Milling Machine Developed in 1860s Combines vertical spindle of drill press with longitudinal and traverse movements of milling. The milling machine is the main machining operations.

There is an oil reservoir and pump in the column to lubricate the spindle. Which forms the foundation of machine on which other parts are mounted. The diagram of cutting operation is shown below.

Save Save Milling machineppt For Later. In milling operation the rate of metal removal is rapid as the cutter rotates at a high speed and has many cutting edges. This milling machine part is the foundation of a milling that carries the weight of the machine and move it to the ground.

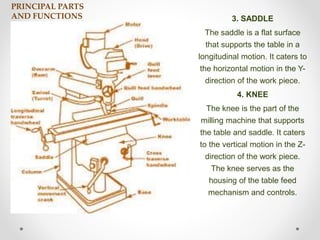

The Milling Machine consists of Base Column Knee Saddle Table Over-Arm Spindle or Arbor Arbor supports Ram and Milling Head. To the axis of the milling machine spindle permitting workpieces to be adjusted in relation to the milling cutter. Horizontal Milling Machine.

MILLING MACHINE OPERATIONS The milling machine removes metal with a revolving cutting tool called a milling cutter. Machining of flat surfaces Slots pockets keyways and profile. The milling head is the upper part of a vertical mill machine.

Milling Machines The basic components of these machines are as follows. Supports the table and can move in the transverse direction. The components of milling machine include.

7 Major Parts of A Benchtop Milling Machine. The column rests on the base and also it has a coolant reservoir and a pump to provide coolant in machining operations. Thus the jobs are machined at a faster rate than with single point tools and the surface finish is.

Milling machine parts. 2 The universal horizontal milling machine also differs from the plain horizontal milling machine in that it is of the ram type. Column and base provide support for the other parts of the milling machine.

The Milling Machine can be performed by both conventional and CNC type. The plain horizontal milling machines column contains the drive motor and gearing and a fixed position horizontal milling machine spindle. This base is made of cast iron due to its high compressive strength.

Vertical milling machine major parts. The milling machine consists basically of a motor driven spindle which mounts and revolves the milling cutter and a reciprocating. These are some important parts of a benchtop milling machine that you need to know.

The electric energy from the outlet is converted into motion and the motion will spin the cutting tools. Some Key Points on Milling Machine. Differences between horizontal vertical milling machines sl.

THE MILLING MACHINE PREPARED BY. PPT Milling Machines PowerPoint presentation free to view - id. Milling is the process of removing metal by feeding the work past a rotating multipoint cutter.

Supports can be moved along the. Column including base is the main casting that supports all other parts of milling machine. It is used to cut slots grooves and drill and perform all operation like to.

Horizontal milling machine vertical milling machine 01 spindle is. A typical motor for benchtop milling machine. This machine can hold one or more number of cutters at a time and rotates at high speed to remove the metal at.

The Surface finish achievable is RA value in microns 32. What Are the Parts of A Milling Machine. All component is mounted on the base.

The turning tool has of several cutting edges. The following stated below are the milling machine parts. On which the workpiece is clamped using T-slots.

Parts of Horizontal Milling Machine. Column houses main drive transmission system spindle. The column rests on the base and base contains coolant reservoir and a pump which is used during machining operation that requires coolant.

Milling machine is used to machining the metal workpiece by a revolving cutting tool. Here in this Milling machine diagram you can easily see Its parts. The milling cutter rotates at a very high speed because of the multiple cutting edges it cuts the metal at a very fast rate.

219 Milling machine cutter and work-piece position Milling machine cutter and workpiece position The milling is a process of metal-removing by feeding the workpiece passes through the rotating multipoint cutter. MILLING is the process of machining flat curved or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges. The source of energy.

100 3 100 found this document useful 3 votes 520 views 35 pages. Milling machine is used to form various types of parts in the industries because it can machine all shape and size work piece. The column contains an oil reservoir and a pump which lubricates the spindle.

We compile them from the top to the bottom as the following. Radial Milling Machine Manufacturer - Tengzhou ROOY CNC Machine Co is a machine tool manufacturing company that has gained global recognition in design and production of machine tools such as milling drilling lathe power presses and other machine tools for metal forming processes. It is the foundation.

The arm and arbor supports are used to stabilize long arbors. This machine can also hold single or multiple cutters at the same time. Ie the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column.

A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter. The milling cutter usually used to cut the metal perpendicular to the tool axis. Column and base provide supports for the other parts of a milling machine.

A milling machine consists of the following parts. The company has been in existence for more than a decade and has endeavored to. The table moves longitudinally relative to the saddle.

In this process workpiece is fed beside a turning cylindrical tool. The Cutting tools used are made up of HSS CARBIDE material. Milling machine is used for machining flat surfaces contoured surfaces surfaces of revolution external and internal threads and helical surfaces of various cross-sections.

So let discuss all of these parts in detail. 1base 2column 3spindle 4spindle head 5knee 6saddle 7worktable 23. We will study one by one in detail.

The turning tool has of several cutting edges.

Simple Indexing In Milling Machine

What Is Milling Machine Operation Parts And Types Mechanical Booster

Milling Cutters Tools Types And Their Purposes With Images

5 Whys Template And Root Cause Analysis Genroe 5 Whys Business Process Mapping Process Improvement

Purchasing Procurement Process Flow Chart Process Flow Chart Process Flow Flow Chart

Lathe Vs Milling Machine What S The Difference Monroe Engineeringmonroe Engineering

Cutting Tool Applications Chapter 10 Boring Operations And Machines American Machinist

Getting Concept To Car Faster Fast Cars Concept Cnc Training

Lathe Machine Fully Explained Hindi Youtube

What Is Machining Intro To Machine Shop Processes Tools

Machine Tool Basic Machine Tools Britannica

Strimmer Trimmer Chainsaw Saw Cutter Carb Carburettor For 43 49cc Engine Wish Carburetor Chainsaw Trimmers

Combing Machine Diagram Comber Diagram Passage

Parts Of Cnc Machines Mechanical Power Inc

Milling Machine Parts Types Operations Milling Cutter Pdf

The Vertical Milling Machine Ppt Download

Milling Machine Parts Types Operations Milling Cutter Pdf

What Is Milling Machine Operation Parts And Types Mechanical Booster